Semi-finished product assembly processes

Work in the semi-finished product assembly includes:

- PCBA and parts assembly: Assembling of the power board, LED board, projector, reflector, and other parts as the semi-finished parts for the next processes of productions

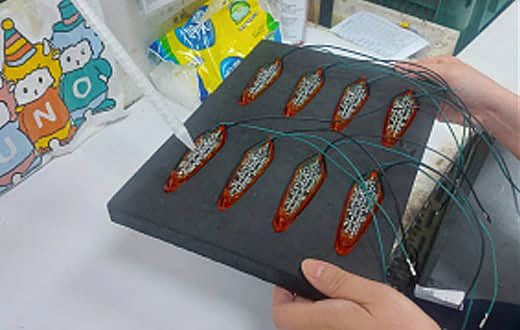

- Stamping / UV glue / AB glue: Fixing, gluing, and sealing components

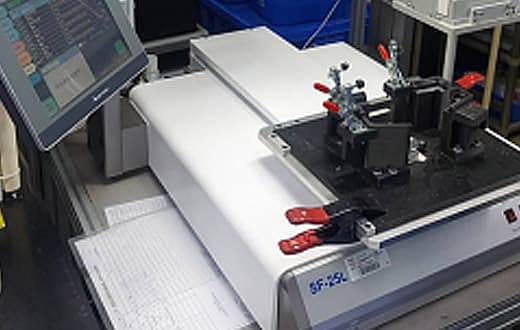

- Confirmation of light beam pattern and light points for testing: Using an online photometric tester to confirm the light beam pattern and major test points comply with the required regulations

Equipment

| Desktop glue spreader | Includes an XY table and a glue supplying equipment. |

| Hot melt glue machine | Add glue on the article to fix components |

| Automatic screw fastening machine | Based on an XY table with electric screwdriver for fastening screws. |

| Stamping machine | Fix parts on the exact positions. |

| Online photometric tester | Confirm the light beam pattern and also some major test points are OK before the final assembly. |

| UV resin dispenser | Using UV light to cure the UV glue immediately for fixing components. |

| AB glue machine | Mixing A glue and B glue for sealing and joining components. |

Desktop glue spreader

Screwing job

Automatic screwing

Hot melt adhesive

Stamping

UV resin dispenser