ELECTRICAL ENGINEERING

During lighting product development, electrical engineering plays an important role in defining electrical specifications and attesting the electrical functions.

First, all teams involved in the lighting product development discuss and verify customer requirements in terms of electrical specifications and operating functions. Other aspects such as the electric circuit type and possible manufacturing process are also discussed.

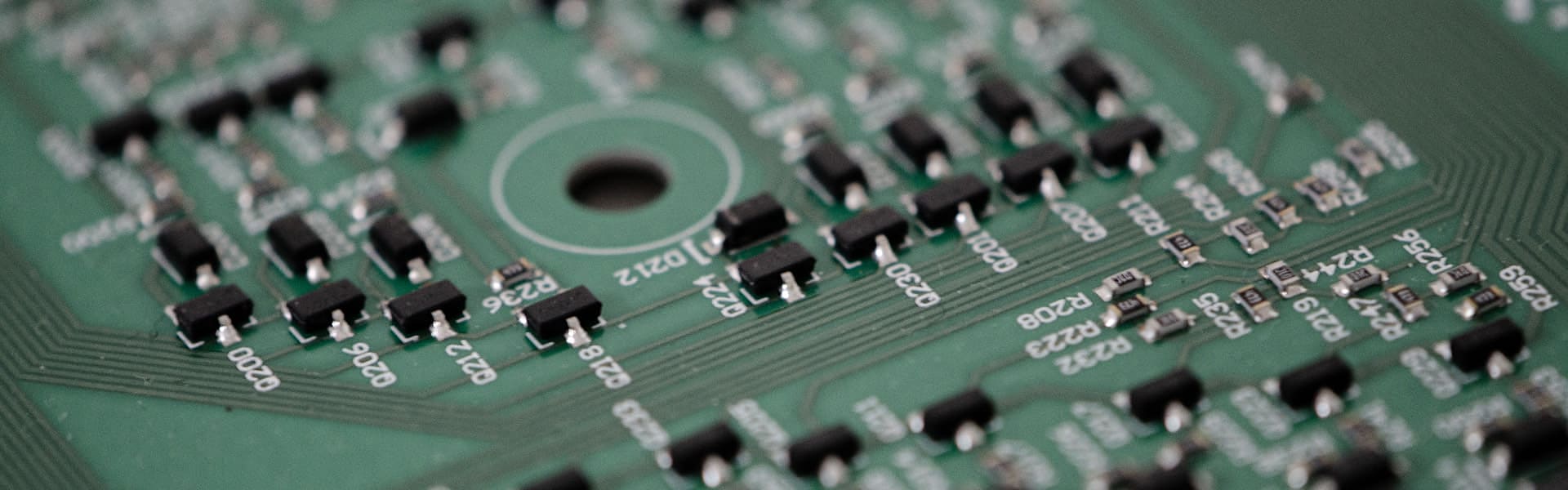

Second, the functional tests of PCB layout and PCBA will be done, based on the suggestions after the electrical specification assessment. These tests include preliminary PCBA functional tests, temperature resistance of electronic components, and EMC standard tests.

Altium Designer

The most widely used software for designing electric circuits and PCB layouts in the electronics industry. It streamlines the circuit design process enabling engineers to go through the design process from schematic to PCB layout. Engineers can also convert the design to 3D files in the PCB design process, and check with other units whether there will be assembly and matching problems.

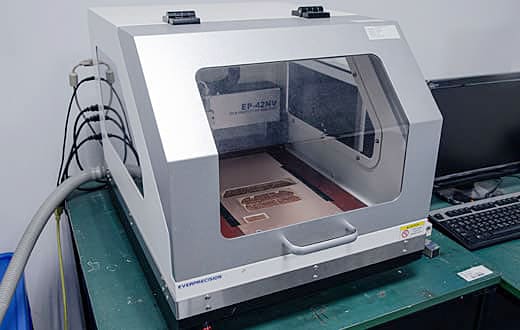

PCB Layout Engraving Machine

After the PCB layout is completed, the PCB engraving machine makes the PCB blank board to verify the preliminary circuit functions.

Power Supply

Through precisely controlling voltage and current of the light input power supply, the machine checks changes of the light under different power supply conditions and tests whether the light meets the expected result of the circuit design.

Transient Tester for Vehicles

The equipment simulates the impact of high voltage surge on the circuit and tests the circuit’s durability and reliability. This test ensures that the lamp will not fail due to surging voltage.

Thermal Imaging Camera

After the optical light distribution confirmation is completed, the reliability and regulatory requirements are preliminarily tested Temperature measurement equipment for electronic parts: infrared thermal imaging camera.

Oscilloscope

This machine tests every circuit node signal of the lamp and assesses whether the circuit meets the default state of the design.

Radiated Emission Circuit Radio Interference Meter

This meter detects the intensity of radio wave interference generated when the lamp is on. This test ensures that final light product will not create strong radio waves interfering other devices inside the vehicle .

Static Electricity Tester

This equipment tests the lamp’s resistance to static electricity. This process ensures the final product’s static electricity does not damage the lamp.