| Stencil Clean Machine |

Put stencil in solvent and washed by ultrasonic automatically. Clean the solvent residual with air pressure gun |

| Laser Engraving Machine |

Set letters or barcode to be put on PCB by laser engraving for the purpose of recognition and tracing back. It can be a barcode, QR code, or DataMatrix. |

| Automatic Printer |

Optical points of PCB and Stencil match with each other to print solder paste on PCB preparing for the coming automatic insertion process. |

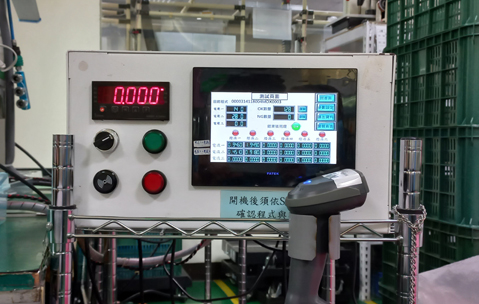

| Solder Paste Inspecting Machine |

Use solder paste inspecting machine to inspect the printing status on PCB and sort out all PCBs that with discrepancy (such as deviation, omission). This is to avoid producing defective products |

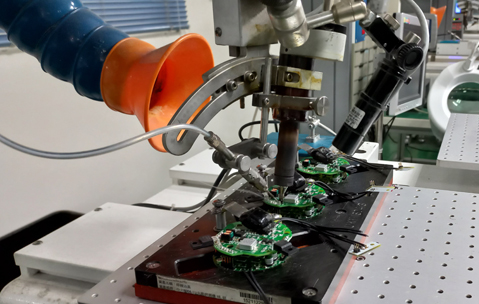

| Insertion Machine |

The equipment picks up the components by vacuum and carries out the image recognition. After all components are recognized exactly, all components will be inserted to the exact positions according to the setting of coordinates. Small components are picked and placed by rotating nozzle and it can pick 12 components maximum at one time. Large or special-shaped components (such as connectors….) are picked and placed by a single suction nozzle. |

| Reflow |

Provide thermal energy through the furnace temperature setting, the solder paste can be melted completely, and ensure all components are joined with the PCB firmly. |

| AOI |

Use trichromatic lens to scan and check if there are missing or offset components on the PCB and also confirm if the soldering situation of every component is normal. It can reduce the risk of misjudgments by manual visual inspection. |

| X-Ray |

Perform air bubble detection on 2 samples from production of each batch |